Unlocking Business Potential with Blister Packing Machine China: The Future of Packaging and Manufacturing

In the rapidly evolving landscape of pharmaceutical, food, and consumer goods industries, efficient packaging solutions are paramount to ensuring product safety, compliance, and consumer appeal. Among these solutions, the blister packing machine China industry stands out as a sector experiencing exponential growth, driven by technological innovation, cost efficiency, and a proactive approach to quality management. For entrepreneurs, manufacturers, and investors aiming to capitalize on this booming marketplace, understanding the intricacies, advantages, and future trends of blister packing machines in China is essential.

Why Choose China for Blister Packing Machine Manufacturing?

China has long been recognized as the manufacturing hub of the world, offering unparalleled benefits for businesses seeking high-quality, cost-effective packaging machinery. The blister packing machine China industry exemplifies this, combining advanced technology with competitive pricing to meet diverse industry needs.

- Cutting-Edge Technology: Chinese manufacturers invest heavily in R&D, incorporating the latest automation, precision engineering, and data integration into their blister packing solutions.

- Cost Efficiency: Lower production costs enable companies like ShineBenMach to offer affordable yet reliable blister packing machines without compromising quality.

- Customization & Flexibility: Chinese suppliers provide tailored solutions compatible with various product types, including pharmaceuticals, candies, and electronic components.

- Robust Supply Chain: An extensive supply chain network ensures timely delivery, maintenance support, and availability of accessories and spare parts.

Key Features & Advantages of Blister Packing Machines from China

The blister packing machine China industry emphasizes features that align with current market demands, such as versatility, automation, and integration capacity. Some of the prominent features include:

1. Versatile Packaging Capabilities

Modern blister packing machines can handle a wide array of products, including tablets, capsules, sachets, and small electronic components. China’s manufacturers lead in designing multi-functional machines that can be quickly adapted for different product formats, thus supporting diverse business needs.

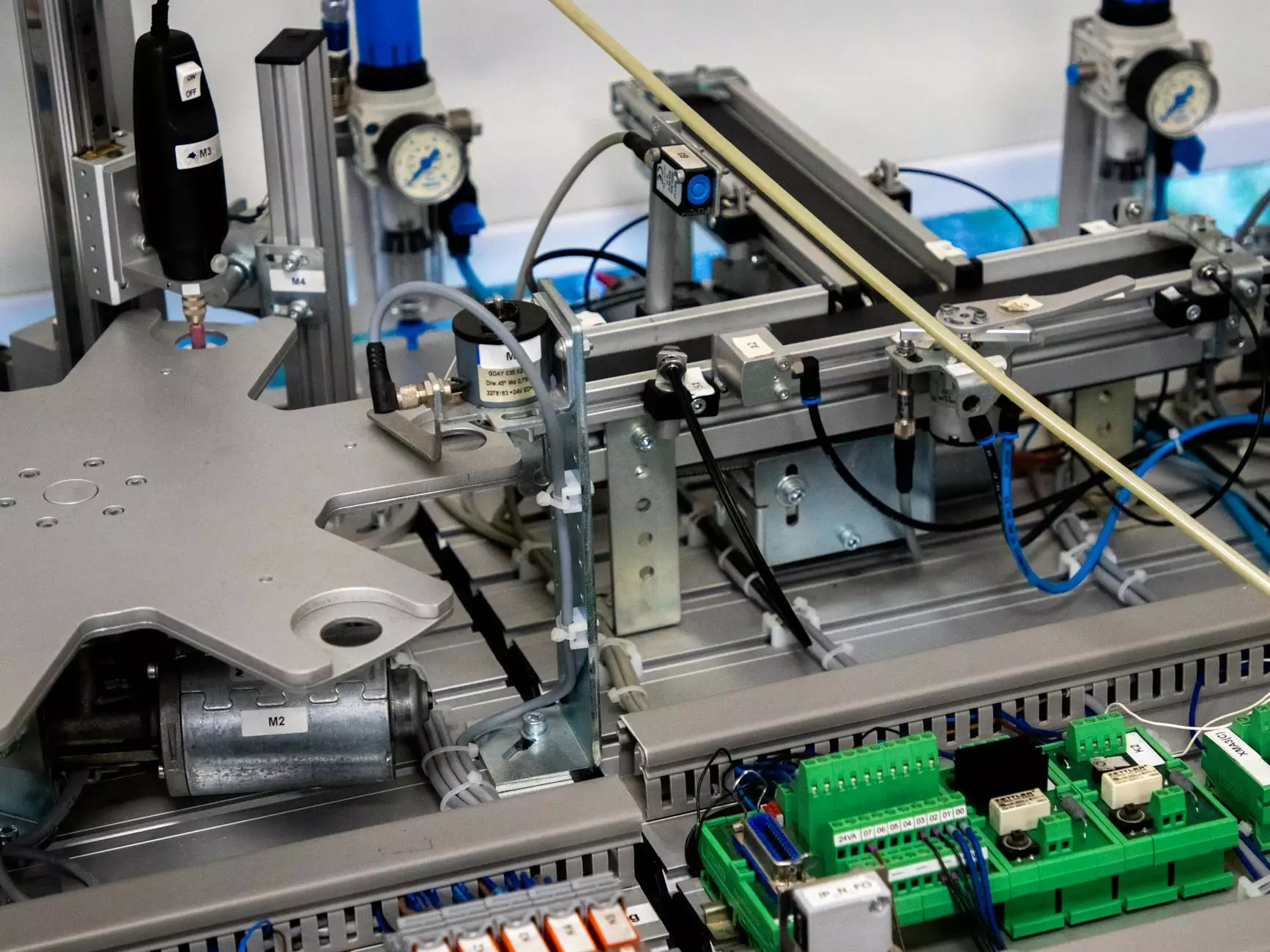

2. Advanced Automation & Control

Automation enhances efficiency, reduces labor costs, and minimizes errors. Many Chinese blister packing machines incorporate HMI (Human Machine Interface), PLC control systems, and real-time monitoring, facilitating seamless operation and quick changeovers.

3. Compliance with International Standards

Blister packaging machinery from China often meets standards such as CE, GMP, ISO, and FDA regulations, ensuring global acceptance and adherence to safety protocols.

4. Energy Efficiency & Sustainability

With increasing global emphasis on eco-friendly manufacturing, Chinese manufacturers integrate energy-saving technology, reduce waste, and promote sustainable production practices.

Accessories and Customization: Enhancing Your Blister Packing Line

To optimize functionality, the blister packing machine industry in China offers a proprietary range of accessories that enhance performance and adapt to specific industry needs:

- Conveyor Systems: For seamless product transportation and packaging line integration.

- Cleaning & Sterilization Attachments: Critical for pharmaceutical applications requiring sterile environments.

- Printer & Coding Modules: For batch numbers, expiry dates, and branding.

- Filling & Sealing Modules: To improve sealing integrity and accommodate various blister sheet types.

- Cooling & Hardening Units: For materials needing precise temperature control during packaging.

Partnering with Chinese manufacturers like ShineBenMach provides access to a wide array of accessories. Custom configurations enable businesses to tailor their packing lines, improve throughput, and ensure compliance with industry standards.

Integrating 3D Printing with Blister Packing Machinery: Innovating Production

One of the groundbreaking advancements in the blister packing industry is the integration of 3D printing technology. Chinese companies are pioneering this frontier, offering innovative solutions that enhance production, customization, and prototyping capabilities.

Benefits of 3D Printing in Business Operations

- Rapid Prototyping: Quick development of custom molds and components, reducing lead times.

- Cost Savings: Lower tooling costs for small batch production or custom packaging designs.

- Design Flexibility: Ability to create complex geometries and specialized blister formats.

- On-Demand Manufacturing: Producing spare parts or modifications on-site, minimizing downtime.

How 3D Printing Enhances Blister Packing Equipment

By incorporating 3D printed parts into blister packing machines, Chinese manufacturers improve machine agility, support bespoke packaging solutions, and facilitate maintenance. For example, custom sealing components, spacers, or alignment guides can be immediately produced, ensuring minimal disruption to production lines.

Why Partner with ShineBenMach for Your Blister Packing & Accessories Needs?

ShineBenMach is a leading Chinese manufacturer specializing in high-quality blister packing machines and accessories. Their commitment to innovation, quality, and customer satisfaction positions them as the go-to partner for global businesses.

Why Choose ShineBenMach?

- Comprehensive Product Range: From fully automated blister packing lines to specialized accessories, ShineBenMach offers everything needed for a complete packaging solution.

- Customization Capability: Tailored machines designed to match specific industry requirements and product specifications.

- ISO & CE Certification: Ensuring safety, quality, and compliance with international standards.

- Rich Experience & Technical Support: Skilled engineers and dedicated customer service facilitate onboarding, troubleshooting, and after-sales support.

- Affordable Pricing & Fast Delivery: Competitive rates paired with efficient logistics to meet tight deadlines.

Future Trends in the Blister Packing Machine China Industry

The industry is poised for significant transformative changes fueled by technological advancements and shifting market demands:

1. Greater Automation & AI Integration

Future blister packing machines will leverage artificial intelligence and machine learning to optimize throughput, predict maintenance needs, and guarantee quality consistency.

2. Smart Packaging Solutions

Enhanced connectivity allowing real-time data sharing, remote monitoring, and integration with warehouse management systems will streamline entire supply chains.

3. Sustainability & Eco-Friendly Materials

Chinese manufacturers are focusing on biodegradable blisters and energy-efficient machinery to meet global green standards.

4. Customization & On-Demand Production

More flexible, modular systems will support small batch runs and personalized packaging, helping brands differentiate themselves in competitive markets.

Maximize Your Business Success with the Right Blister Packing Partner

Investing in the right blister packing machine China solutions can significantly elevate your business prospects by offering unmatched efficiency, flexibility, and quality. Whether you are expanding your pharmaceutical lines, launching new consumer products, or innovating with electronic components, the potential is enormous.

Partnering with experienced manufacturers such as ShineBenMach ensures you gain access to cutting-edge machinery, comprehensive accessories, and expert support to stay ahead in today's competitive marketplace.

Final Thoughts: Seize the Opportunity in the Blister Packing Industry

The blister packing machine China industry offers a fertile ground for business growth, innovation, and competitive advantage. With advancements in automation, customization, and sustainability, companies can significantly improve their production processes and product quality. By leveraging partnerships with reputable Chinese manufacturers, entrepreneurs can minimize costs while maximizing quality and efficiency, opening doors to new markets and higher profitability.

Stay ahead of the curve, embrace technological integration like 3D printing, and choose a reliable partner like ShineBenMach to transform your packaging and manufacturing capabilities today.